Sometimes all it takes is a spark of collaboration to ignite a true wave of innovation. That’s exactly what happened when RMA joined forces with PUT Motorsport from Poznan University of Technology.

One Goal, One Team.

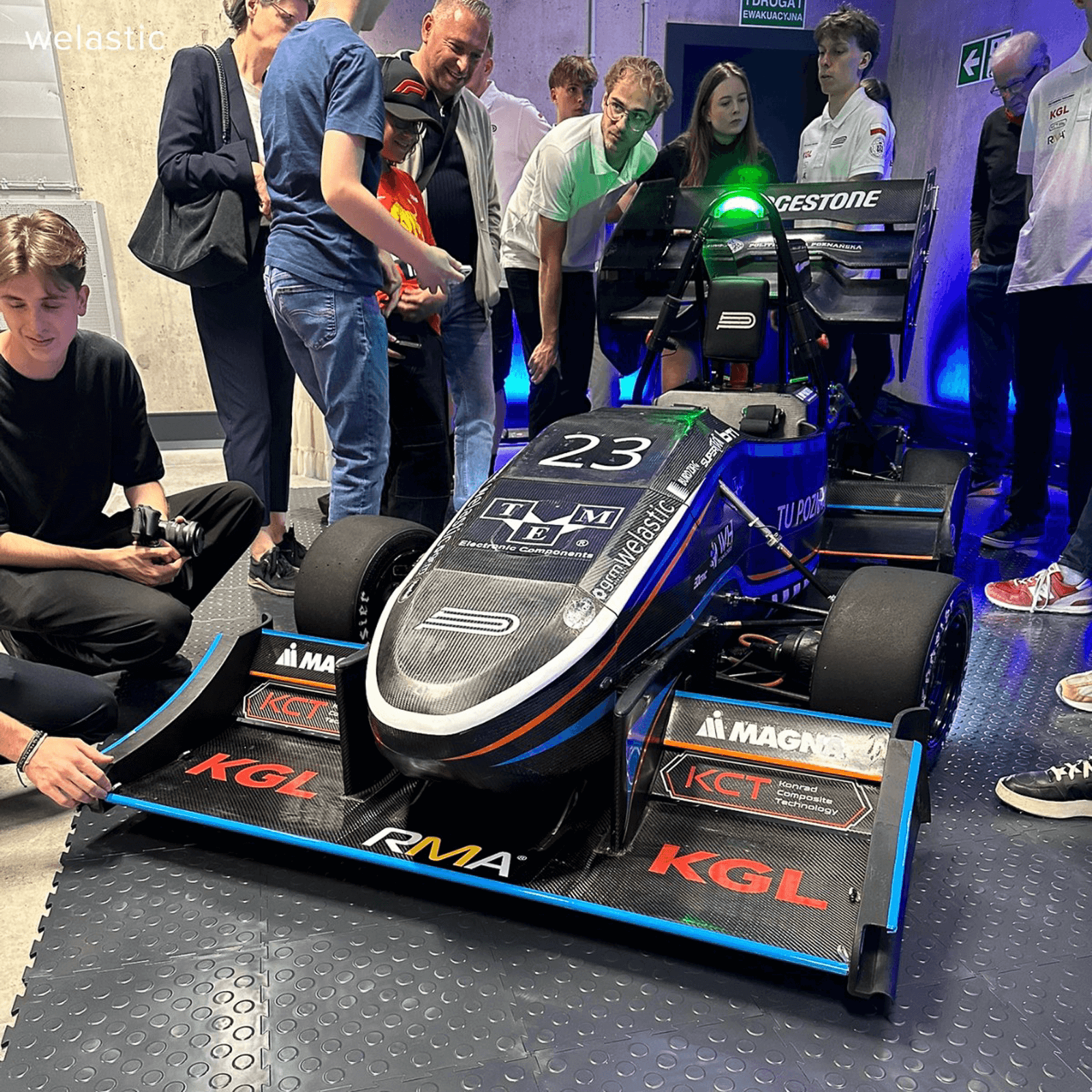

To create a more efficient and reliable power system for an electric race car set to compete in the prestigious Formula Student competition.

Technology that fuels performance

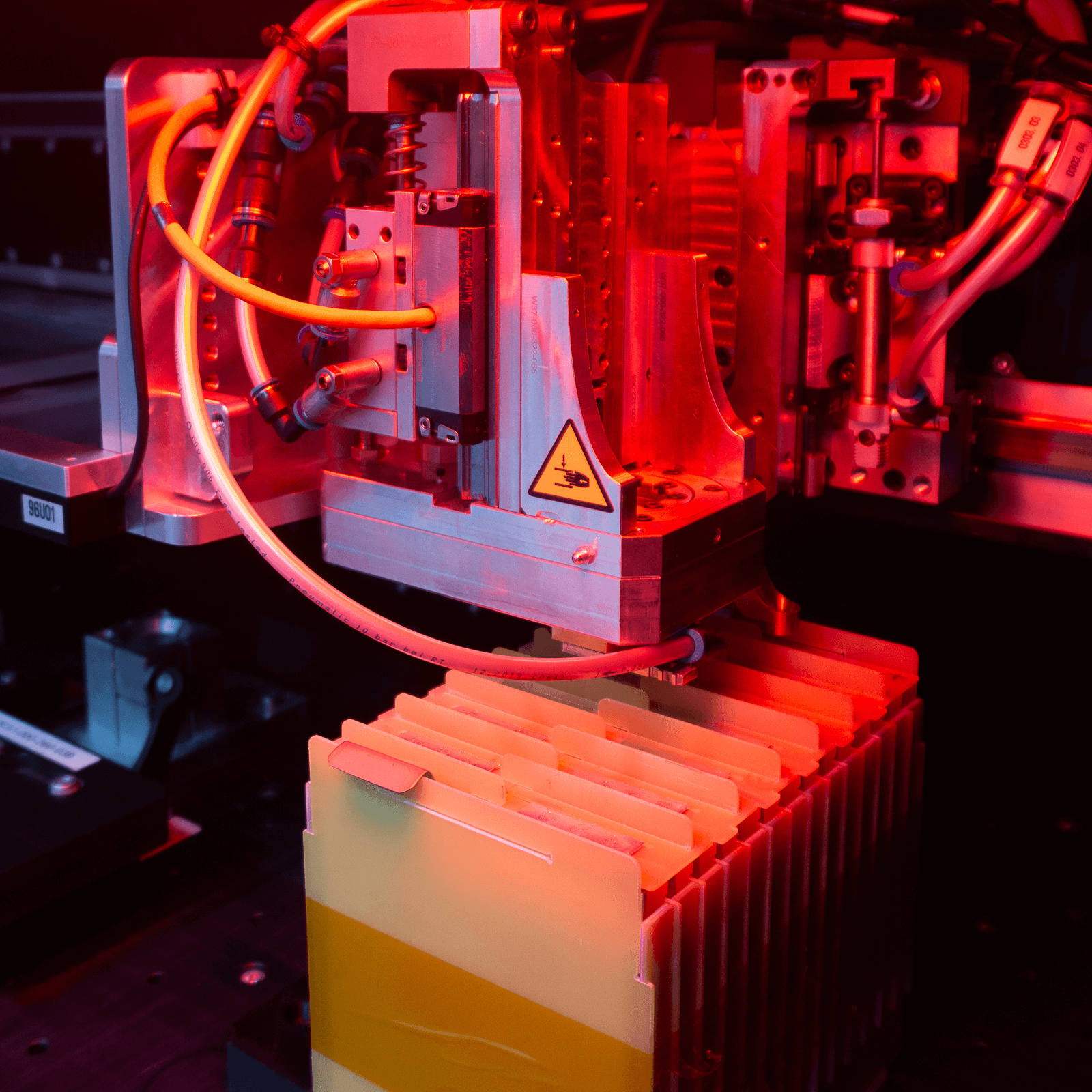

For years, RMA has been delivering cutting-edge solutions to the battery industry — particularly in the field of laser welding, which enables exceptionally precise joining of components. It’s a technology that increasingly forms the backbone of modern electromobility.

The collaboration with PUT Motorsport created the perfect opportunity to combine academic insight with industrial expertise. The student team designed a battery based on Pouch cells — a solution growing in popularity in modern electric systems. RMA specialists supported the team in laser-welding aluminium–copper connections, which require outstanding precision and strict process control.

The result? A durable assembly of 140 pouch cells into 10 modules, with work that previously took weeks completed in just one day.

“The laser-welded joints met — and even exceeded — our expectations. They are incredibly precise and highly repeatable,” emphasize the PUT Motorsport team.

Faster, safer, better

In previous years, students had to manually spot-weld hundreds of cells — a demanding and time-consuming process. Thanks to RMA’s technology, battery production accelerated by 1–2 months, and the team was also able to prepare additional spare modules.

Automated laser welding also significantly improves safety — it reduces the risk of short circuits and burns, while producing joints with lower resistance. This translates into lower energy losses and reduced operating temperatures. As the students themselves admit, “our latest battery performs much more consistently than previous designs — even during the most demanding runs.”

Knowledge in motion

The PUT Motorsport team has been active since 2014. Driven by a passion for engineering and motorsports, the students design, build and test race cars that later compete on tracks across Europe. For them, Formula Student is more than just a competition — it’s a future-focused laboratory where they learn teamwork, project management and the application of advanced technologies.

“Working with RMA helped us understand industrial standards and see how high-quality components are really made. It’s experience that will undoubtedly benefit us in our future careers,” the team members highlight.

Success breeds success

In the 2025 season, PUT Motorsport competed at the legendary Hockenheimring during Formula Student Germany, as well as at Autodrom Słomczyn during Formula Student Poland. The team returned to Poznań with several achievements — including 3rd place in the Autocross event and one of the top Endurance times.

Yet results aren’t the only thing that matters. This is tangible proof that collaboration between industry and academia truly works — enabling young engineers to turn knowledge into practical solutions, while companies like RMA can test their technologies under the most demanding real-world conditions.

A shared direction: the future of electromobility

The joint project by RMA and PUT Motorsport demonstrates how much can be achieved when passion, science and technology come together. From precise laser welding in the lab to competitive performance on the racetrack — every stage of this collaboration marks a step toward a more sustainable and advanced future of mobility.

Because it’s exactly at the point where knowledge, precision and determination meet that true innovation is born.

Photos thanks to courtesy of PUT Motorsport