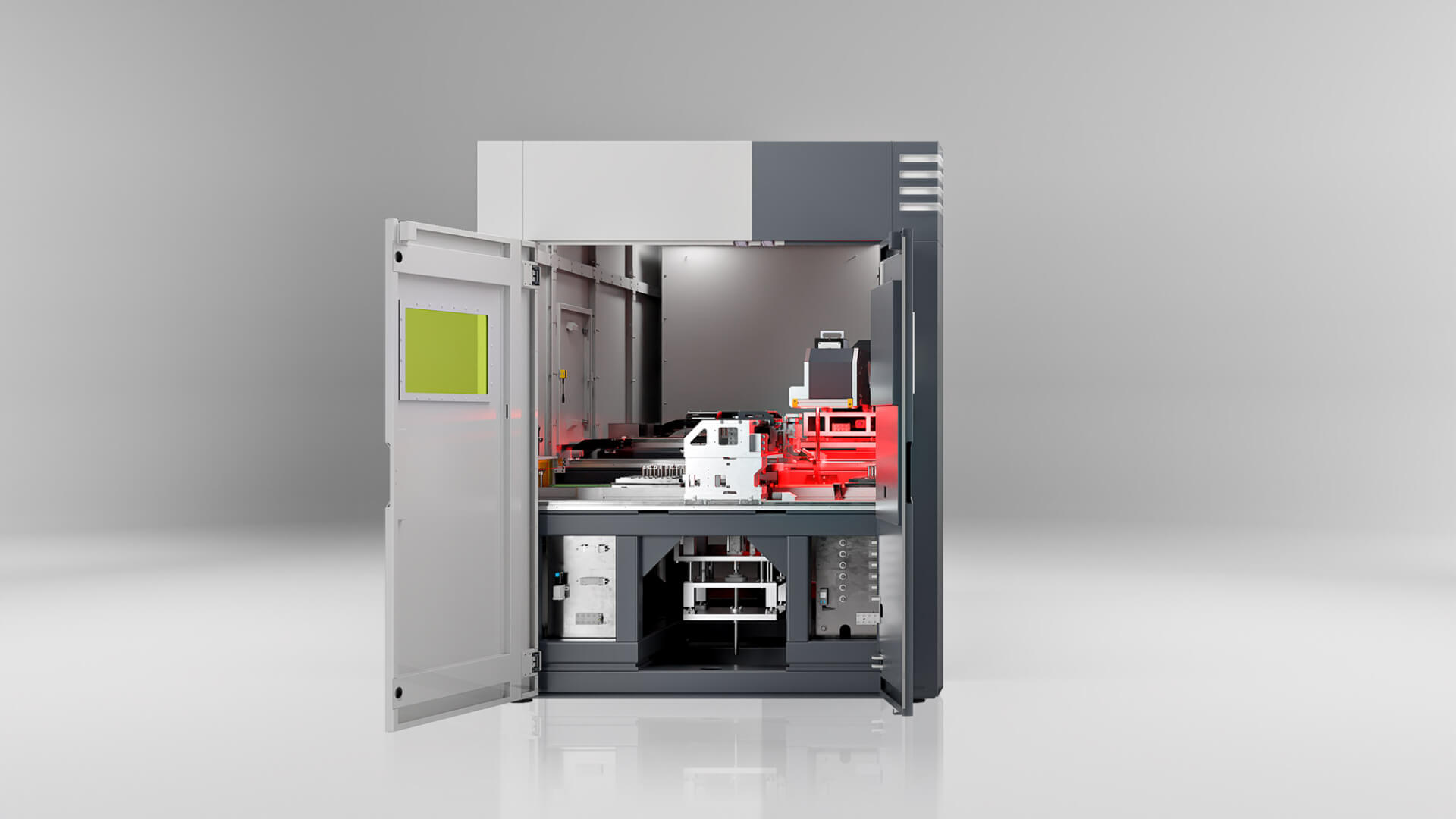

Battery Welder Max

Fully automatic solution for welding battery modules. The solution has been designed for high-performance automatic production lines.

Battery Welder Max is a cutting-edge, high-performance laser welding system engineered for seamless integration into fully automated battery production lines. Its robust, automated design ensures maximum throughput and exceptional consistency, ideal for high-volume manufacturing environments.

Customizable to meet specific production requirements, Battery Welder Max can be optimized for various battery module configurations, ensuring peak efficiency and productivity. Featuring advanced automation technology, the system significantly reduces cycle times and enhances overall production efficiency, making it the perfect choice for manufacturers seeking precision, reliability, and scalability.

Online welding quality monitoring

In-process metrology

Easy adaptation to non-standard technical requirements

| Laser technology gives you the ability to join a wide range of materials (including highly reflective) |

| Easy automation |

| Advanced traceability functions for very high production volumes |

Download the latest RMA Battery Welder series brochure.