Custom projects

Laser welding solutions tailored to the individual needs of our customers.

We carry out projects comprehensively - the implementation phase is usually preceded by advanced technological tests and a thorough analysis of the client's needs and requirements. The projects are entirely carried out within the Company - from design and programming to assembly and commissioning.

Each project is supervised by a specialized and experienced project manager. All this means that over the years the RMA team has developed unique competencies in the field of automation and robotization of production, which actually allow our clients to achieve a competitive advantage and measurable benefits.

In the last few years, we have acquired the position of the leading supplier of innovative and comprehensive solutions for the battery manufacturing industry. We offer tailor-made solutions and ready-to- use platforms for laser welding.

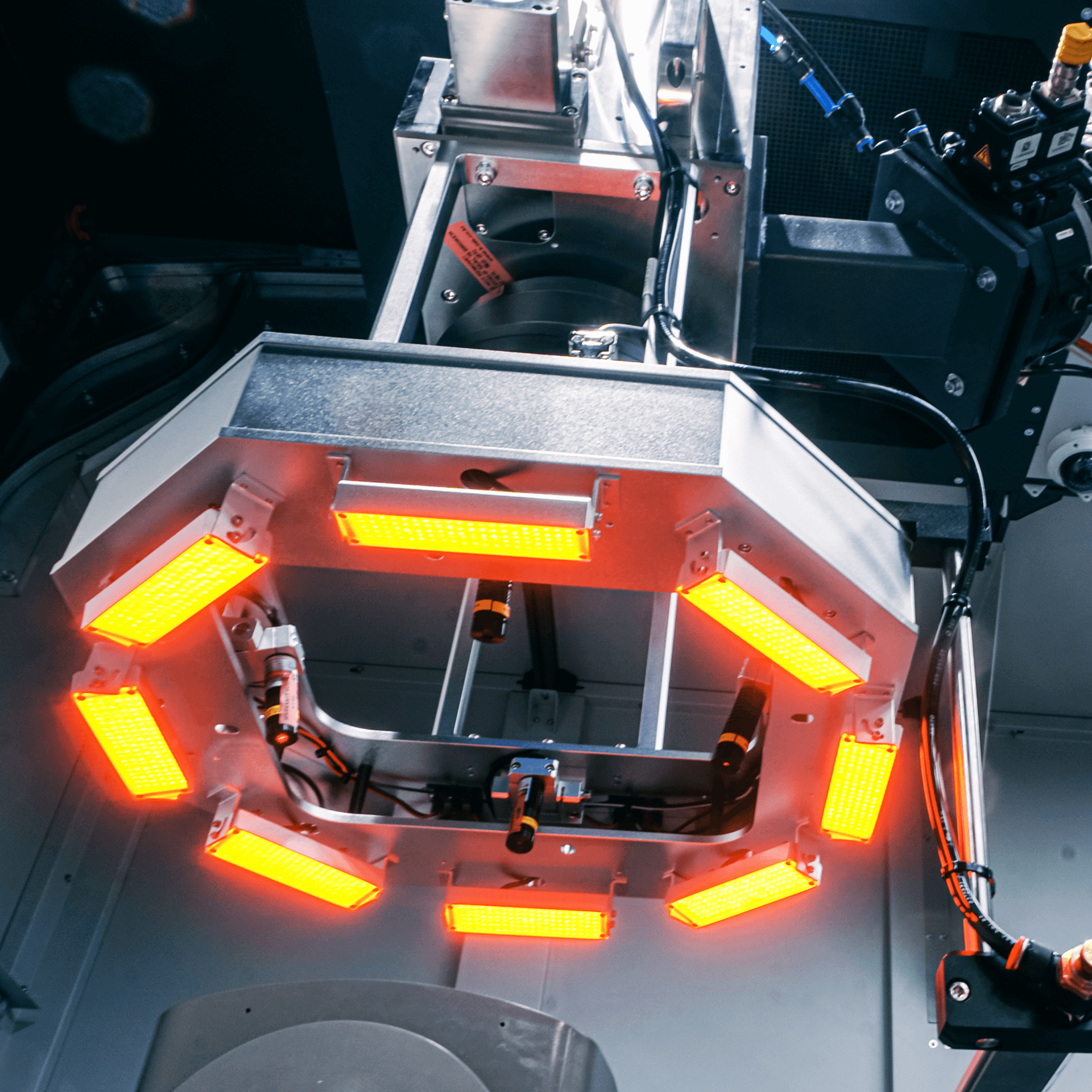

Our profound experience in the area of laser processes, our multidisciplinary engineering team and product specialisation let us design and construct a line of standard machines (Battery Welder), which are efficient and flexible in production and carefully considered in terms of the safety of use. Our competence in the area of laser welding enable us to propose and set up the optimal and repetitive process for components made of various materials. We have experience in welding connectors to cylindrical and prismatic cells

We offer comprehensive solutions for designing efficient and innovative production lines that perform their tasks based on laser processes such as laser welding, 3D cutting, structuring, and laser cleaning.

We carry out line projects comprehensively - the implementation phase is usually preceded by advanced technological tests and a thorough analysis of the client's needs and requirements.

Projects are carried out entirely in-house - from designing and programming to assembly and commissioning.

Each project is supervised by a specialized and experienced project manager.

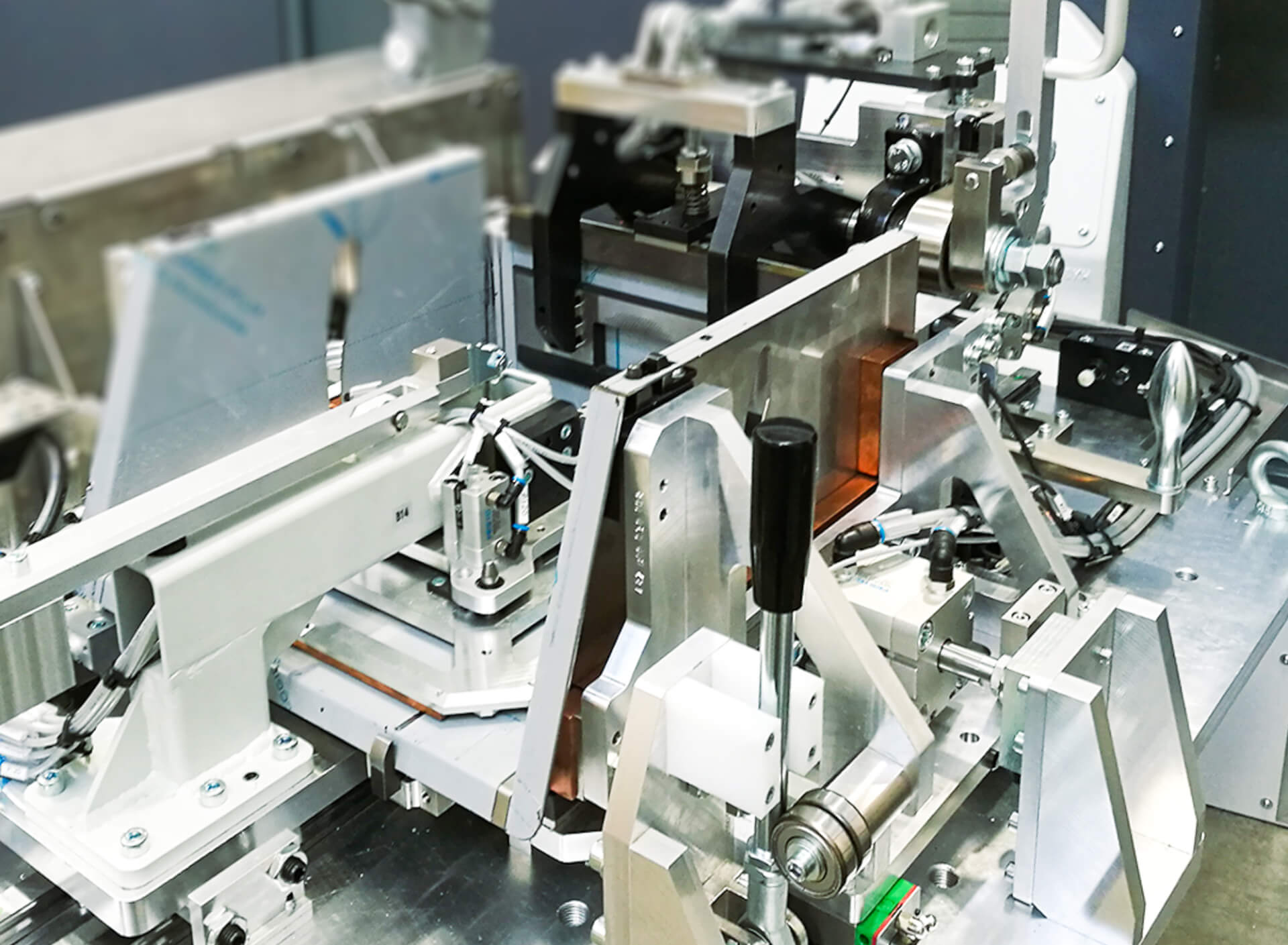

An integral component of all our solutions is specialized and dedicated tooling. We design, test, and commission it as part of the main project. The client does not have to look for other tooling suppliers, as the entire project scope is carried out comprehensively in one place.

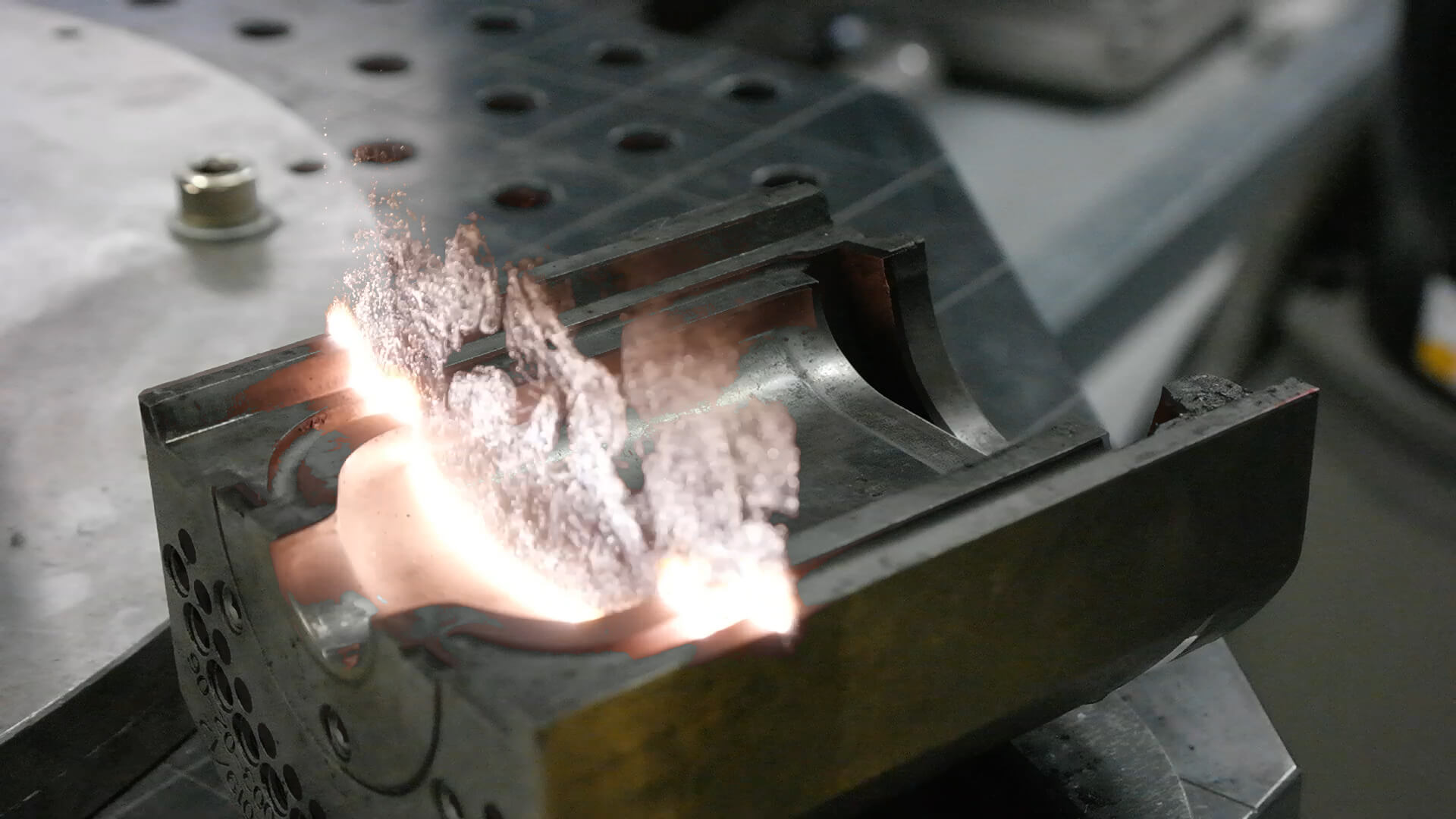

Laser welding is a technology that uses a laser beam to join materials, often in a shielding gas atmosphere. The main advantages of laser welding include: very high process speed, precision, ease of automation, no need for post-processing and high aesthetics of the connection.

In the battery industry, laser welding offers a flexible and efficient approach to joining materials such as copper, aluminum, steel, and nickel.

Laser cleaning technology uses a highly concentrated laser pulse to evaporate contaminants from the surface of processed objects. In contrast to typical abrasive blasting, laser cleaning technology is characterized by much greater process control with minimal impact on the properties of the cleaned surface.

Laser structuring, on the other hand, allows in a controlled way (often selectively) modify the properties of the treated surface (e.g. roughness, hydrophobicity) and facilitates effective implementation of subsequent technological processes (painting, gluing, coating).

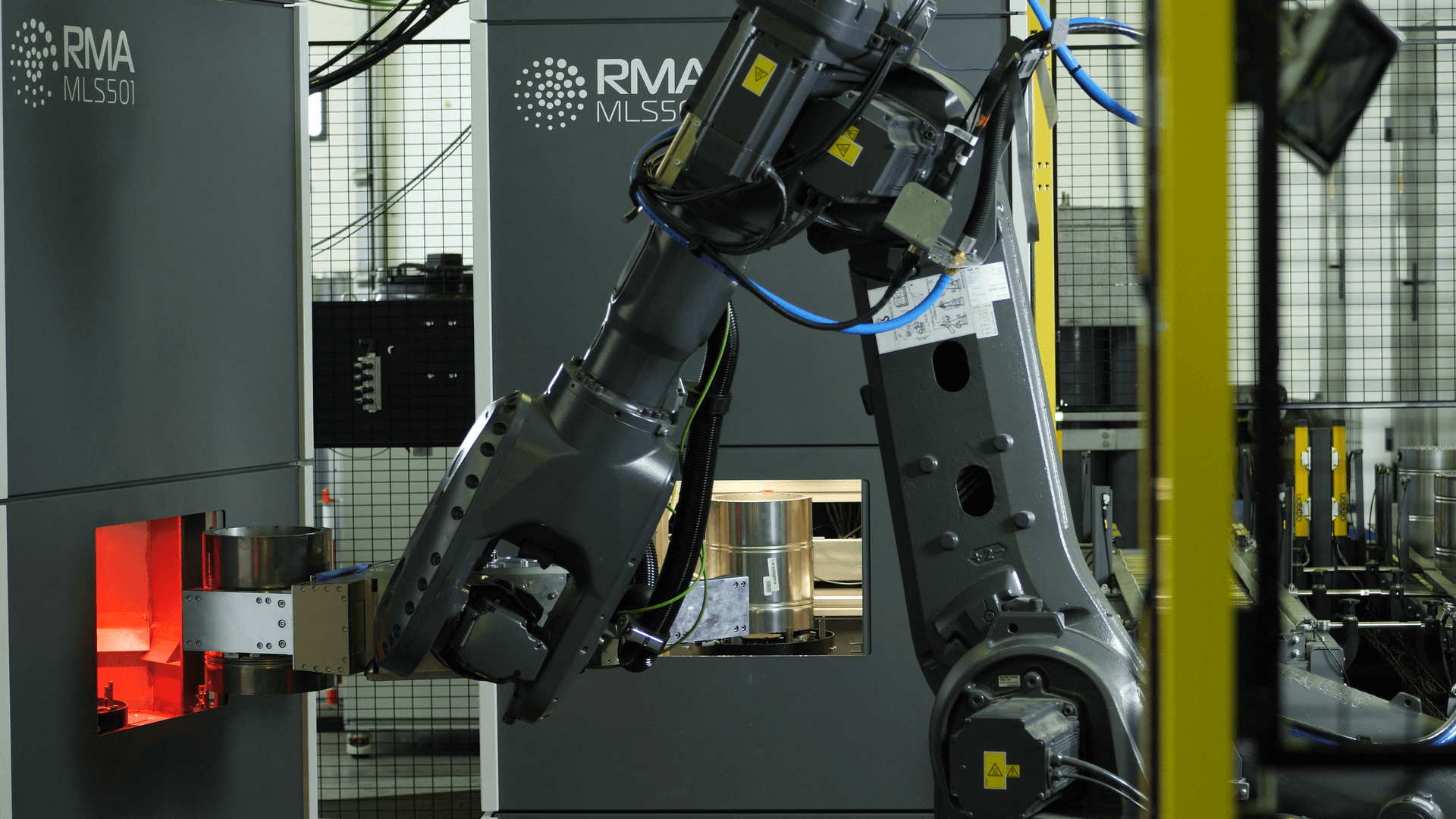

3D laser cutting is a technology that allows the precise cutting of complex shapes and geometry with a laser beam. For this purpose, at RMA, we use a dedicated laser source and a six-axis industrial robot.

We also successfully implement projects of special machines for cutting thin-walled profiles (different materials and thicknesses).

Projects are implemented comprehensively and in accordance with the accepted customer requirements - from the concept phase and needs analysis, through design, assembly, and commissioning.

The solutions produced in this way are delivered with a full range of after-sales services.

|

If you're unsure whether laser processes can be a good alternative in your production area, just contact us!