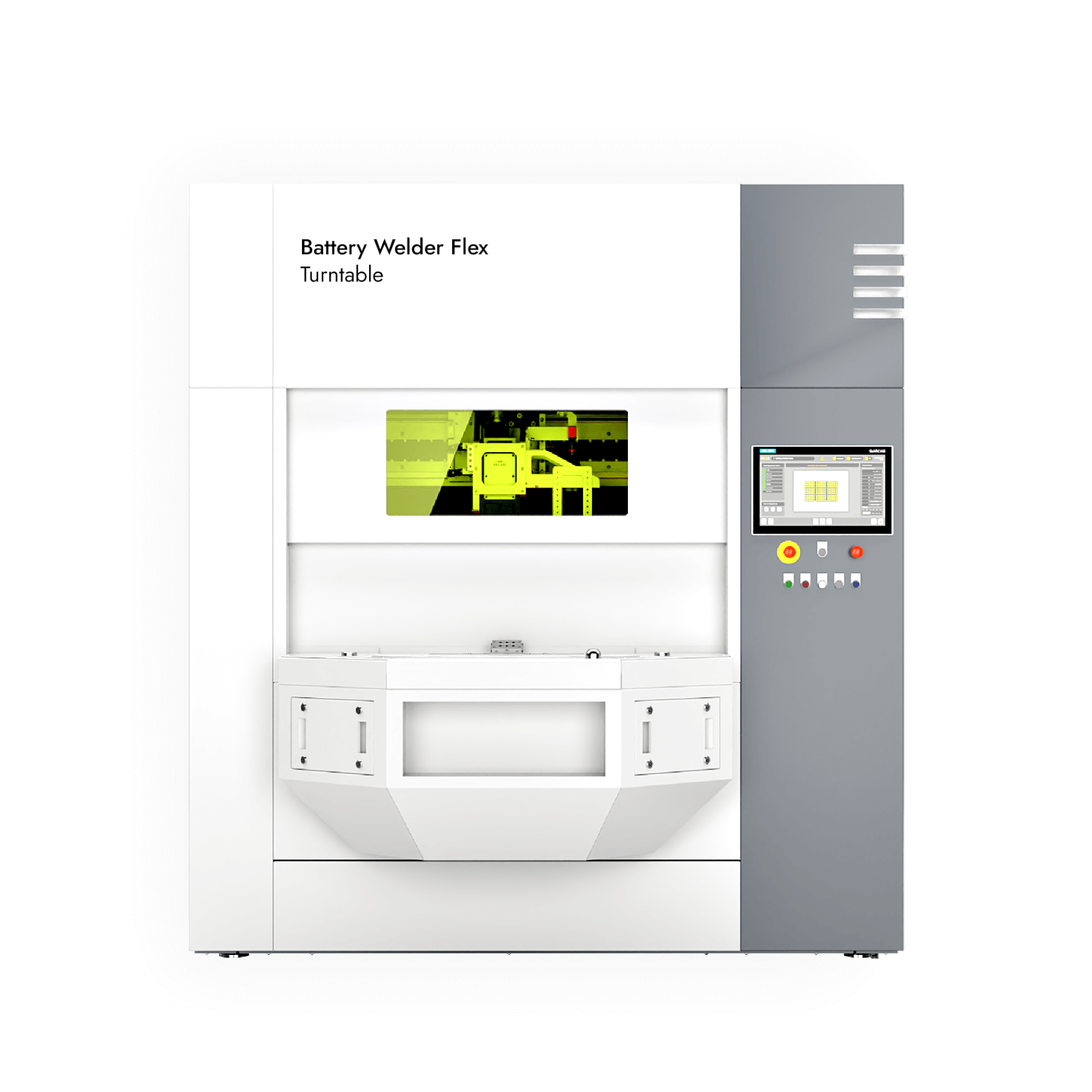

Battery Welder Flex

A fully flexible machine suitable both for R&D and low volume production.

Battery Welder Flex is an advanced, fully flexible laser welding system specifically designed for laser welding of battery modules and packs with exceptional accuracy and efficiency. Its unmatched versatility, rapid changeover capabilities, and intuitive programming make it ideal for both research and development as well as low-volume production.

The system's adaptive design delivers optimal welding results for a variety of cell types, including prismatic, cylindrical, pouch and blade batteries. Precision-engineered components ensure consistent quality and performance, enabling seamless transitions between different products and significant downtime reduction.

Battery Welder Flex empowers your operation with reliability, flexibility, and superior precision for all your battery module welding needs.

Machine dimensions: (LxWxH) 2350x2800x2800 mm

Working pressure: min. 5 bar

Machine power: 15 kW

Weight: 3600 kg

Axis movement speed (max.): 1500 mm/s

Welding speed (max.): 2000 mm/s

Work area:** max. 1200x800 mm, max. height. 300 mm

| Ability to join a wide range of materials |

| Advanced vision system |

| Easy programming / high product flexibility |

Download the latest RMA Battery Welder series brochure.