Precision and Reliability in Battery Manufacturing – The Osterrath and RMA Collaboration in Advanced Laser Welding

11/12/2025

Introduction to RMA and Osterrath GmbH & Co. KG Collaboration

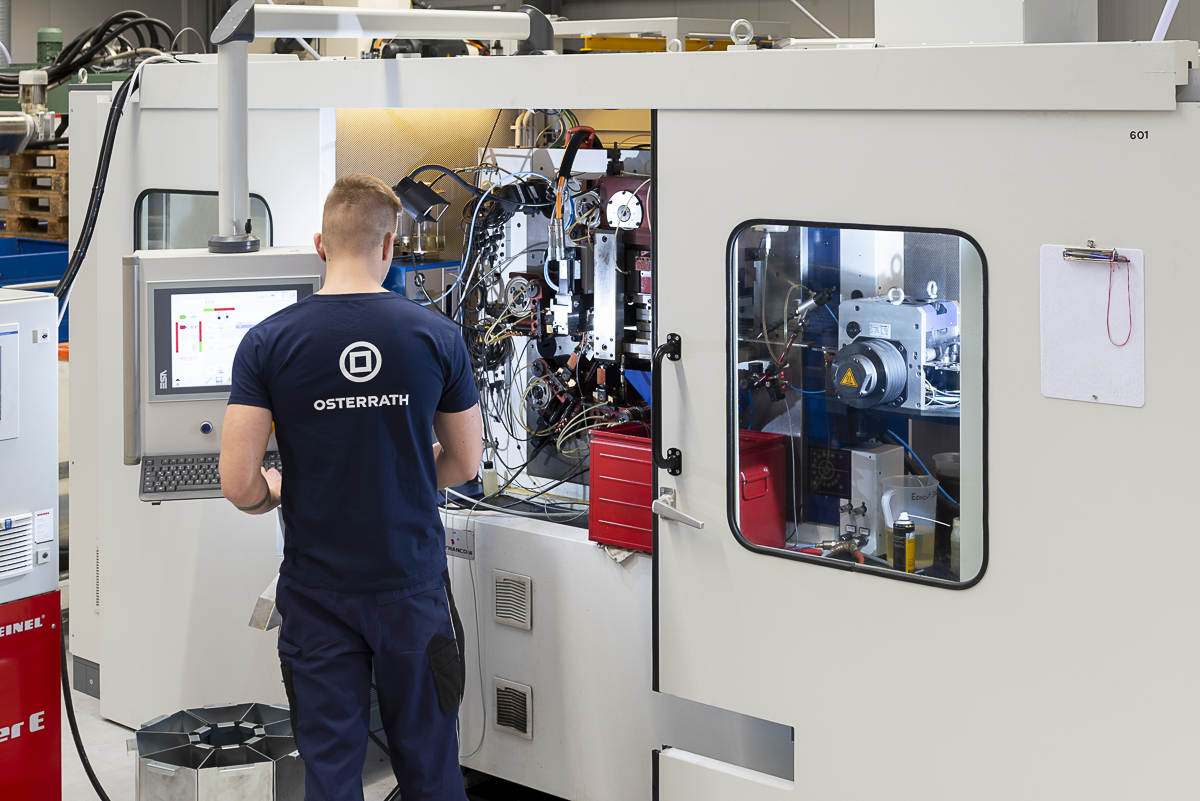

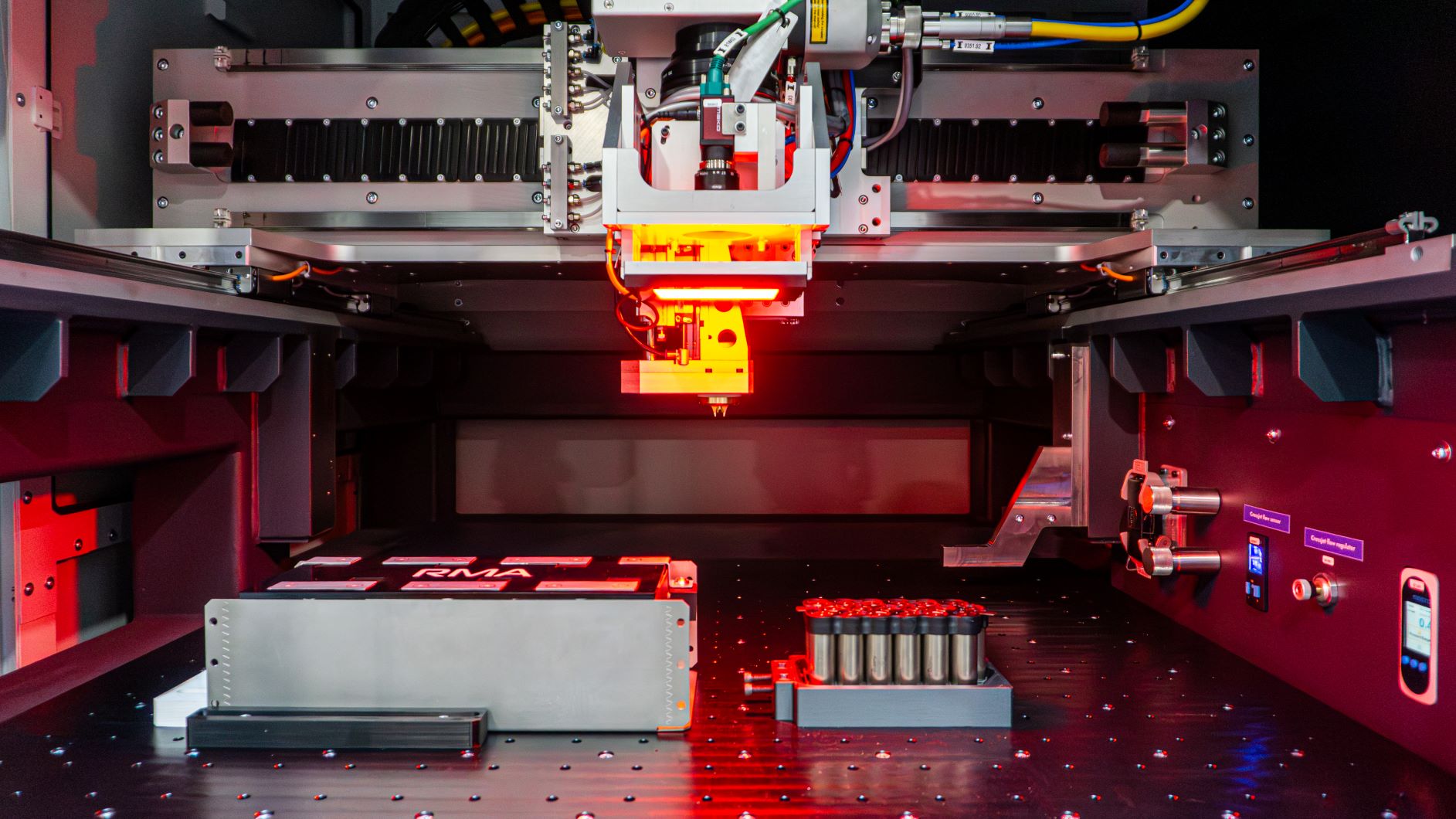

RMA is a leading provider of laser welding solutions for the battery industry, combining deep expertise in laser processing with a multidisciplinary engineering team. Its high-performance, customized systems are designed to meet the evolving demands of battery manufacturing, ensuring precision, reliability, and efficiency.

The Battery Welder series offers exceptional efficiency, flexibility, and top safety standards. Each system is fully customizable for seamless integration into automated production lines. Backed by a state-of-the-art welding laboratory, RMA provides comprehensive support to optimize processes and maximize results.

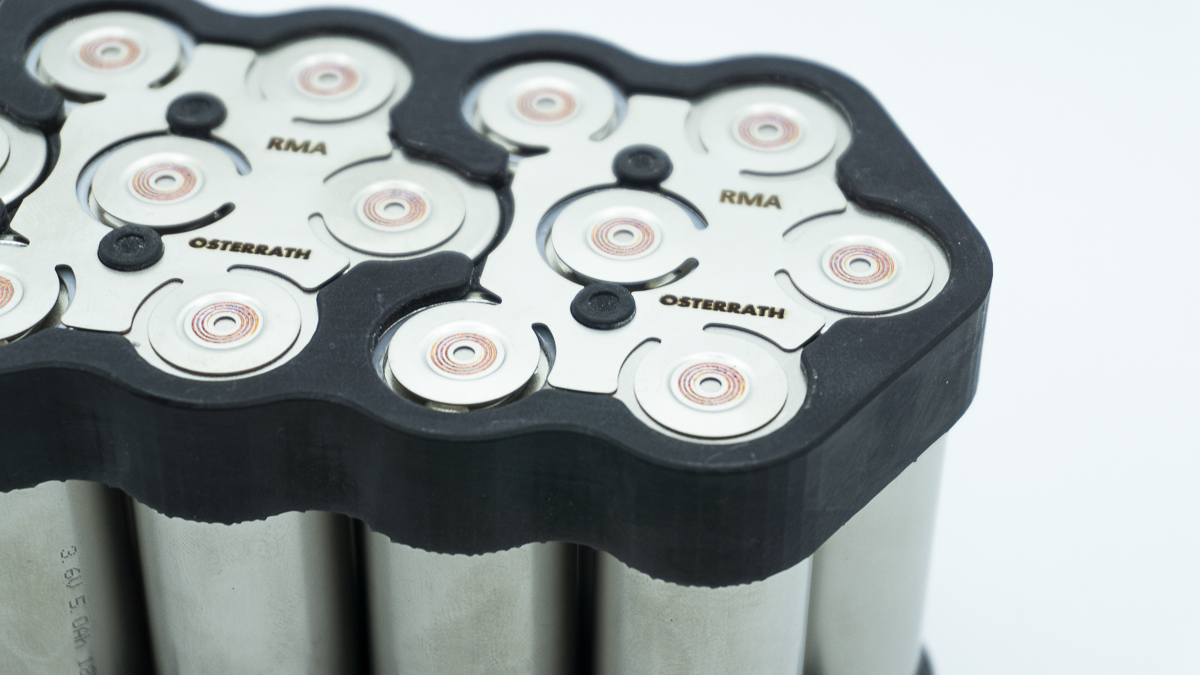

The collaboration between Osterrath GmbH & Co. KG and RMA merges premium connector solutions with advanced laser welding expertise. By integrating Osterrath’s high-quality components with RMA’s specialized process engineering, this partnership delivers welding results that meet the highest standards of strength, conductivity, and consistency.

Osterrath – Key Strengths of Connectors for the Battery Industry

- Material Expertise & Precision

Highly conductive materials such as copper alloys with optimized surface treatments ensure minimal contact resistance and maximum energy efficiency—a decisive factor in high-performance batteries. - Modularity & Adaptability

The development team works closely with customers to tailor connectors precisely to specific cell formats, pack designs, and thermal requirements. This is especially crucial for emerging cell technologies, such as prismatic cells. - Automation & Process Integration

Parts are engineered not only for functionality but also for seamless integration with automated manufacturing processes like laser welding, ultrasonic welding, and robotic assembly. This approach helps reduce production costs while enhancing quality.

Anticipating future challenges—like higher energy densities, new cell chemistries, and sustainability requirements—Osterrath actively designs recycling-friendly materials. Partnering with RMA accelerates bringing these innovations to market.

Materials and Production Standards as Guarantees of Quality and Durability

- Material Selection – Functionality Meets Sustainability

Focus lies on highly conductive materials such as copper alloys and clad copper materials, offering outstanding electrical properties and mechanical stability—critical for the lifecycle of battery composites under thermal and mechanical stresses. - Production Standards – Precision and Process Reliability

Manufacturing adheres to automotive standards with the tightest tolerances, automated inline controls, and full digital traceability. This ensures consistently high quality, less waste, and reliable delivery performance.

Osterrath also develops specialized welding geometries that reduce heat during joining, ensuring long-term contact quality even under intensive charging cycles.

Benefits of Using Osterrath Connectors with Laser Welding Technology

- Performance

Laser-welded connections deliver extremely low contact resistance, enabling less energy loss, higher charging and discharging currents, and improved overall battery module performance. - Safety

Laser welding ensures reproducible, gas-tight connections that minimize risks of contact corrosion or thermal failures. Osterrath connectors are designed to withstand mechanical stress, vibrations, and temperature cycles safely. - Durability

Precise welding and premium materials result in connections with significantly longer service life, even with frequent charging cycles.

Major Welding Performance Advantages from the Osterrath and RMA Partnership

- Joint Quality

Combining precision-manufactured connectors with RMA’s laser welding expertise enables optimized weld seam geometry, resulting in fewer microcracks, enhanced mechanical stability, and superior reproducibility. - Electrical Conductivity

Osterrath’s highly conductive materials, when matched with RMA’s welding parameters, further reduce contact resistance, improving current flow and reducing heat generation. - Process Consistency

Full compatibility with automated laser welding workflows ensures stable positioning, repeatable energy distribution, and reliable joint formation.

Scalability and Future-Proof Battery Production with Osterrath

- Tight Tolerances

High-precision tools and camera-based inline measurement systems ensure micrometer-level quality. - Zero-Defect Quality

Automated controls, digital traceability, and continuous optimization support top performance. - Scalable, Future-Proof Manufacturing

Modular production allows rapid scaling without compromising quality.

"Our connectors are engineered to support manufacturers in scaling production with uncompromised precision and quality, ensuring they meet evolving industry standards and market demands."

—Patrick Sassmann, Head of Development at Osterrath

"The collaboration with RMA enables the integration of these components into highly automated lines, further enhancing process consistency and efficiency at scale."

Conclusion: A Strategic Partnership Shaping the Future of Battery Manufacturing

The collaboration between Osterrath and RMA exemplifies how combining high-quality components with cutting-edge laser welding technology sets new benchmarks in battery production. Together, they deliver superior quality, performance, and safety, offering end users longer-lasting, more reliable batteries while giving manufacturers the confidence to scale production efficiently.

"This partnership enables the production of battery modules that meet the highest standards in strength, conductivity, and consistency—critical factors for future battery technologies."

"By integrating Osterrath’s connector expertise with RMA’s advanced laser welding systems, manufacturers are empowered to create scalable, precise, and reliable production processes ready to meet tomorrow’s challenges."

This partnership truly powers the next generation of battery manufacturing—precise, reliable, and ready for the future.