Laser Welding – Technology Characteristics and Industrial Applications

Laser welding is an advanced material joining technology that uses a high-energy laser beam. This process enables the production of welds with very high quality, repeatability, and mechanical strength while minimizing the heat-affected zone.

Thanks to high energy concentration and precise process control, laser welding is used wherever high accuracy, minimal distortion, and automation capability are required.

What Is Laser Welding?

Laser welding involves focusing a laser beam with a very high power density, reaching levels of 10²–10¹¹ W/mm², onto a small area of material. This concentrated energy rapidly heats the metal to its melting point and, at higher parameters, may also cause partial vaporization.

The laser beam is:

- focused using optical systems,

- guided through mirrors or fiber optics,

- precisely directed to the joint area.

This results in a very narrow fusion zone and a minimal heat-affected zone (HAZ). Reduced heat input lowers the risk of distortion, residual stresses, and structural changes in the base material.

At sufficiently high power density, a keyhole (vapor channel) is formed, enabling deep penetration with a narrow weld.

Types of Laser Welding

Conduction Welding

- relatively shallow penetration,

- wider and aesthetically smooth welds,

- used for thin components and precision parts.

Deep Penetration (Keyhole) Welding

- high penetration depth,

- narrow weld seam,

- ability to weld thicker sections in a single pass.

Laser welding may be performed with or without filler material, depending on joint fit-up and metallurgical requirements.

Advantages of Laser Welding

High Precision

The ability to focus the beam to a very small diameter allows welding of thin-walled components and complex geometries.

Minimal Heat-Affected Zone

- reduced distortion,

- lower residual stresses,

- preservation of base material properties near the weld.

High Weld Quality and Repeatability

- uniform weld structure,

- reduced welding imperfections,

- consistent parameters in serial production.

High Welding Speed

High energy density enables fast processing speeds, which is essential in high-volume production lines.

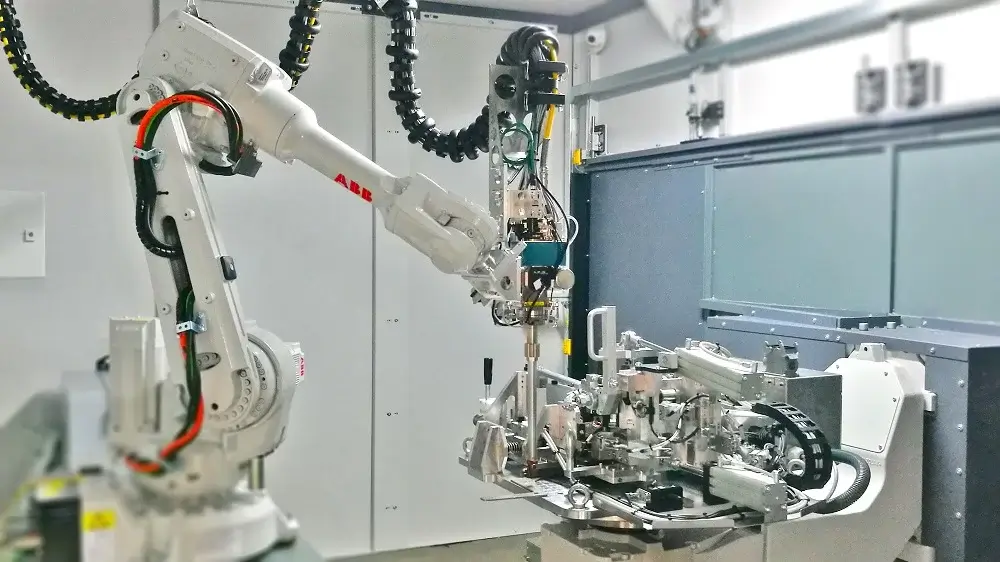

Easy Automation

- robotic systems,

- CNC machines,

- fully automated production lines.

Ability to Weld Difficult Materials

Laser welding is suitable for materials with high thermal conductivity, chemical reactivity, or significantly different physical properties.

Materials Used in Laser Welding

- structural and alloy steels,

- stainless and heat-resistant steels,

- aluminum and its alloys,

- titanium and titanium alloys,

- nickel and nickel-based superalloys,

- copper and selected copper alloys.

Industrial Applications of Laser Welding

Automotive Industry

- body components,

- powertrain parts,

- electric vehicle battery housings.

Aerospace Industry

- lightweight structural components,

- engine parts,

- high-strength precision assemblies.

Energy Sector

- turbine components,

- heat exchangers,

- high-pressure installations.

Laser Welding in Modern Manufacturing

Increasing demands for quality, weight reduction, repeatability, and Industry 4.0 integration make laser welding a key joining technology in modern manufacturing.