Why Use Automated Laser Cleaning Instead of Conventional Methods?

Conventional cleaning methods, such as manual abrasion or sandblasting, face several critical technical and operational limitations, including:

- Risk of damage to delicate surfaces due to aggressive mechanical abrasion,

- Generation of large amounts of solid and dust waste requiring proper disposal and negatively impacting the environment,

- Emission of potentially toxic fumes and dust posing health risks to operators,

- Process effectiveness depending on operator skill and precision, affecting repeatability and quality of results.

In contrast, automated laser cleaning uses high-energy laser pulses to precisely remove unwanted surface layers without mechanical contact with the treated material.

Principle of Laser Cleaning

The process is based on laser ablation, which involves selective vaporization (sublimation) of contaminants and organic or inorganic coatings under short laser pulses with strictly controlled energy and wavelength. This results in thermal decomposition of the surface layer without damaging the substrate, eliminating solid waste generation and the need for chemicals.

Key Advantages of Automated Laser Cleaning Systems

- Automation and Repeatability: Programmable laser beam control ensures consistent process parameters, guaranteeing high repeatability and minimizing operator errors.

- Non-contact Processing: Absence of physical contact protects surfaces from mechanical damage.

- Environmental Friendliness: The process requires no chemicals or abrasives and does not generate waste or harmful emissions.

- Efficiency and Time Optimization: Fast and precise contaminant removal reduces cleaning cycle time and operational costs.

- Access to Hard-to-Reach Areas: Laser systems, often equipped with robotic arms or 3D scanners, can clean complex geometries inaccessible to traditional methods.

Industrial Applications of Laser Cleaning

1. Rust Removal and Surface Preparation of Steel for Coating

Corrosion (rust) and oxide layers degrade the mechanical and adhesive properties of metal surfaces. Laser ablation effectively removes rust, oils, greases, and hydrate compounds while preserving substrate integrity and optimally preparing the surface for further processing.

2. Surface Preparation for Welding and Bonding

Laser cleaning removes contaminants and oxides that cause weld defects and weaken adhesive bonds. The process results in welds with improved uniformity, porosity-free surfaces, and enhanced corrosion resistance.

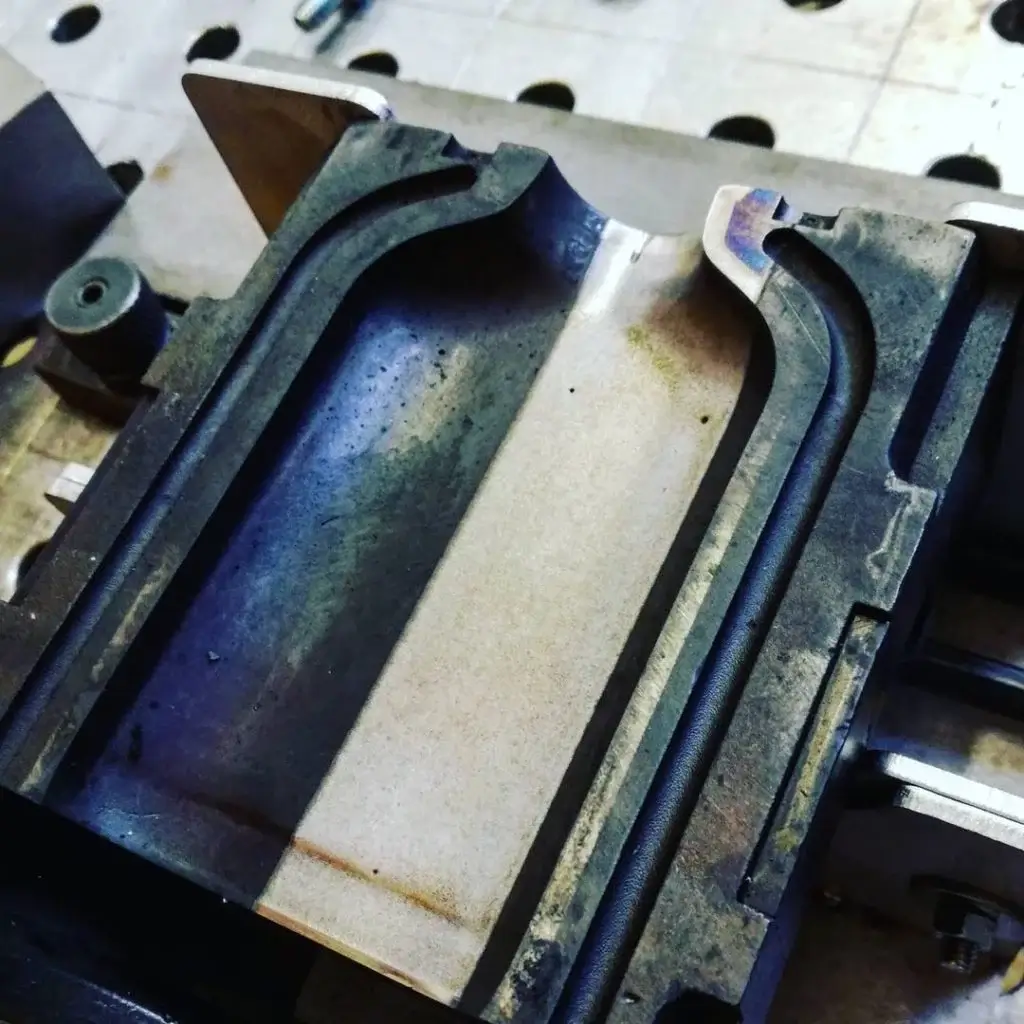

3. Removal of Welding Discoloration

Discoloration and oxide layers formed due to high temperatures and magnetic field changes during welding can be efficiently removed by laser ablation, with precise adjustment of laser parameters according to material type and coating thickness, including on galvanized surfaces.

4. Selective Removal of Paint and Coating Layers

Thanks to precise control of laser pulse energy, the process enables selective removal of top paint and lacquer layers without damaging primers, which is critical in industries demanding high precision, such as electronics and automotive.

5. Cleaning Graphite Electrodes in Electrolytic Processes

Removing contaminants and deposits on graphite electrodes improves their lifespan and the efficiency of aluminum production. Laser cleaning ensures accuracy without damaging the electrode structure.

Summary

Automated laser cleaning technology is increasingly replacing traditional surface treatment methods due to its precision, repeatability, and eco-friendly profile. Its applications span a wide range of industries—from medical laboratories through electronics to metallurgy. In an era of rising demands for quality, safety, and environmental protection, laser cleaning is becoming the gold standard for removing surface contaminants.