Laser Welding in Key Industrial Sectors

Laser welding is a versatile technology that enables numerous connections within battery modules, including:

- Connectors and tabs

- Busbars

- Casings (Enclosure)

- Measurement connections

- Fuses

- Other parts

Applying laser technology significantly expands the possibilities of joining materials that were previously challenging or impossible to weld using traditional methods. This allows for the design of more efficient batteries, meeting rising user requirements and supporting new applications.

Materials Suitable for Laser Welding

Laser technology enables welding of various materials, including dissimilar ones such as:

- Steel

- Copper (nickel-coated)

- Nickel

- Aluminum

- Layered materials

Industrial Applications of Laser Welding

The versatility of laser technology in battery pack welding makes it suitable for numerous industrial sectors, including:

- Electromobility (EV) – electric vehicles

- Power Tools and Garden Tools

- Energy Storage Systems (ESS)

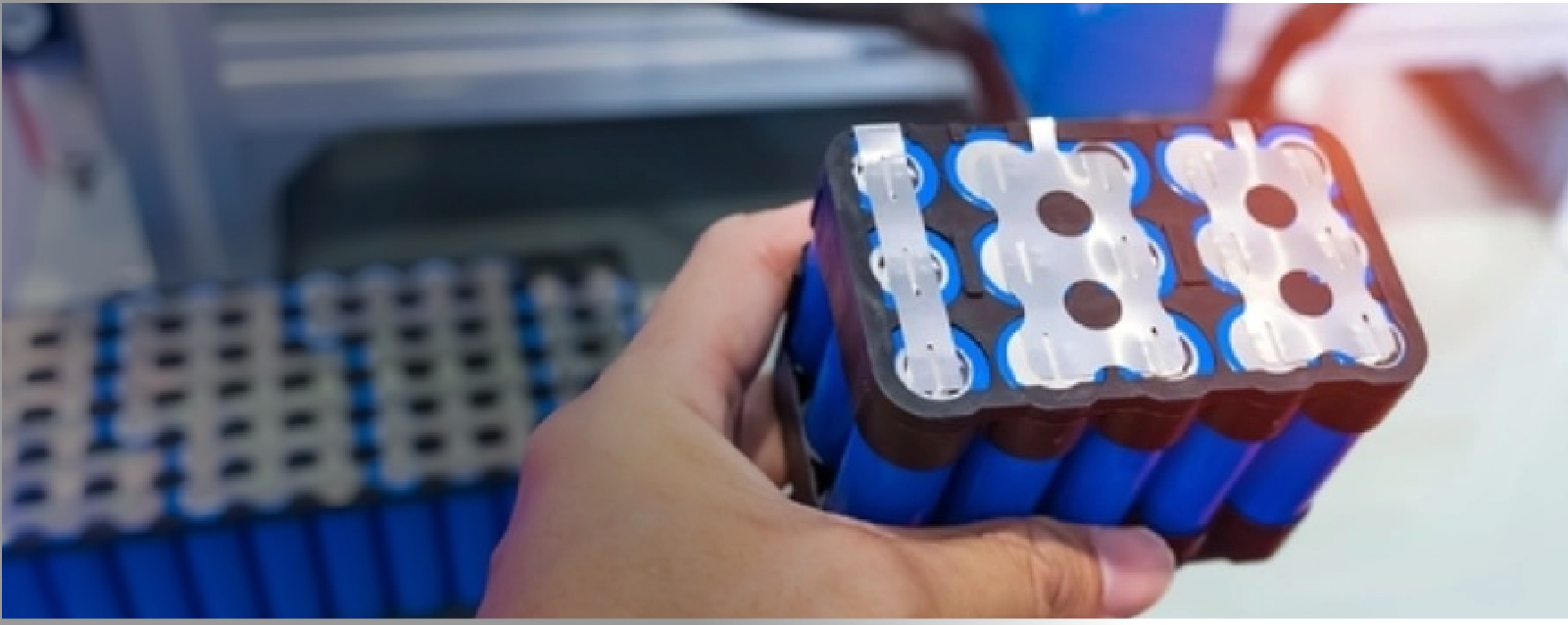

Flexibility in Lithium-ion Cell Types

The high flexibility of laser welding technology enables the use of various lithium-ion cell types, including:

- Cylindrical cells (18650, 21700, 46XX) – welded both single-sided (crimp) and double-sided

- Prismatic cells

- Blade cells

- Pouch cells

RMA Battery Welder – Advanced Laser Welding Solutions for the Battery Industry

Machines from the RMA Battery Welder series are specialized laser welding systems offering:

- Highest welding precision, ensuring minimal connection resistance,

- Compatibility with various cell types, from cylindrical to prismatic and blade,

- Process automation, reducing production time and increasing repeatability,

- Minimized thermal impact, protecting cells from overheating.

Laser welding is a crucial element of modern battery manufacturing. Investing in advanced solutions like the RMA Battery Welder allows manufacturers to enhance process quality and efficiency, meeting the increasing demands of the energy and electromobility markets.

Discover more about the technology in the technology section.

Contact us via the contact form.