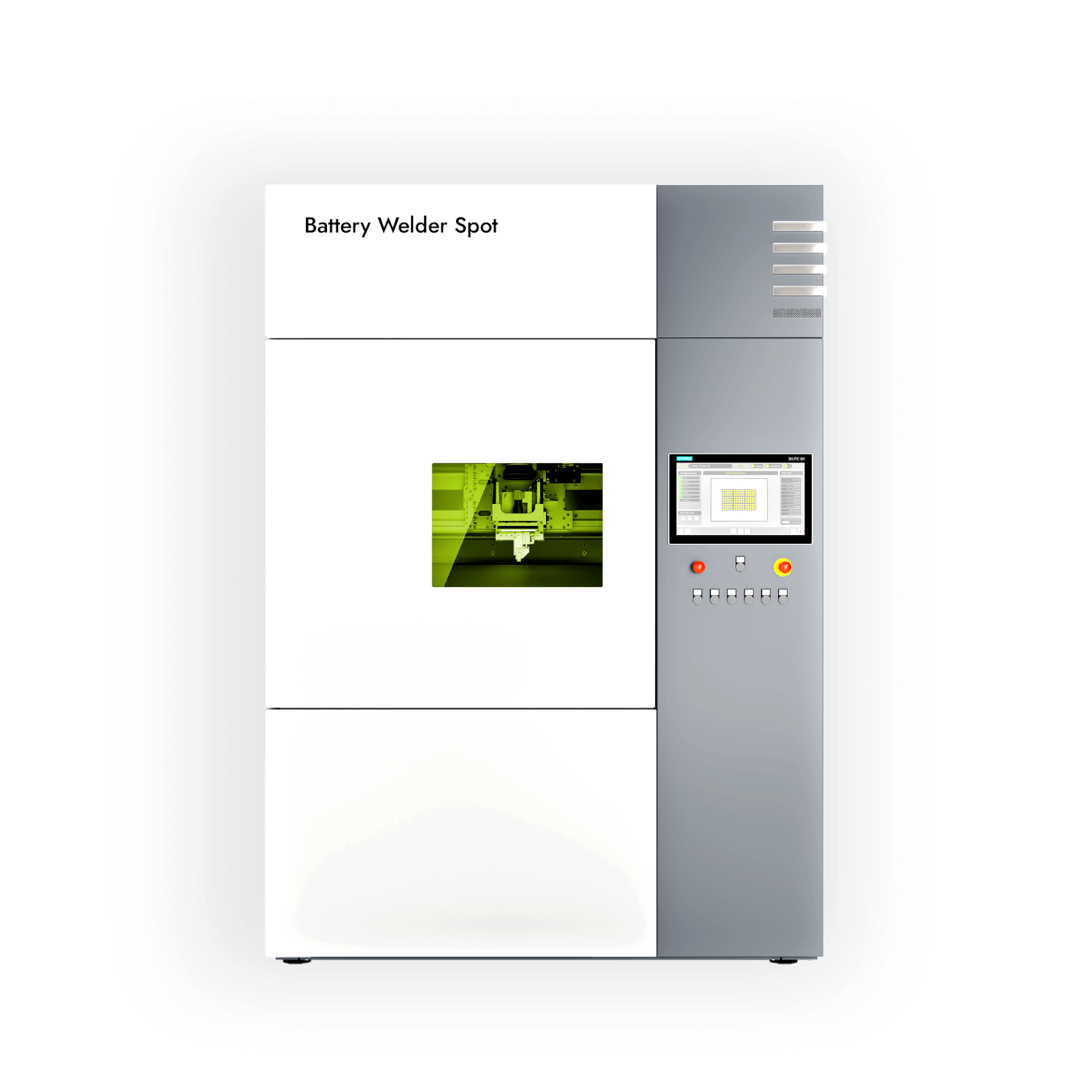

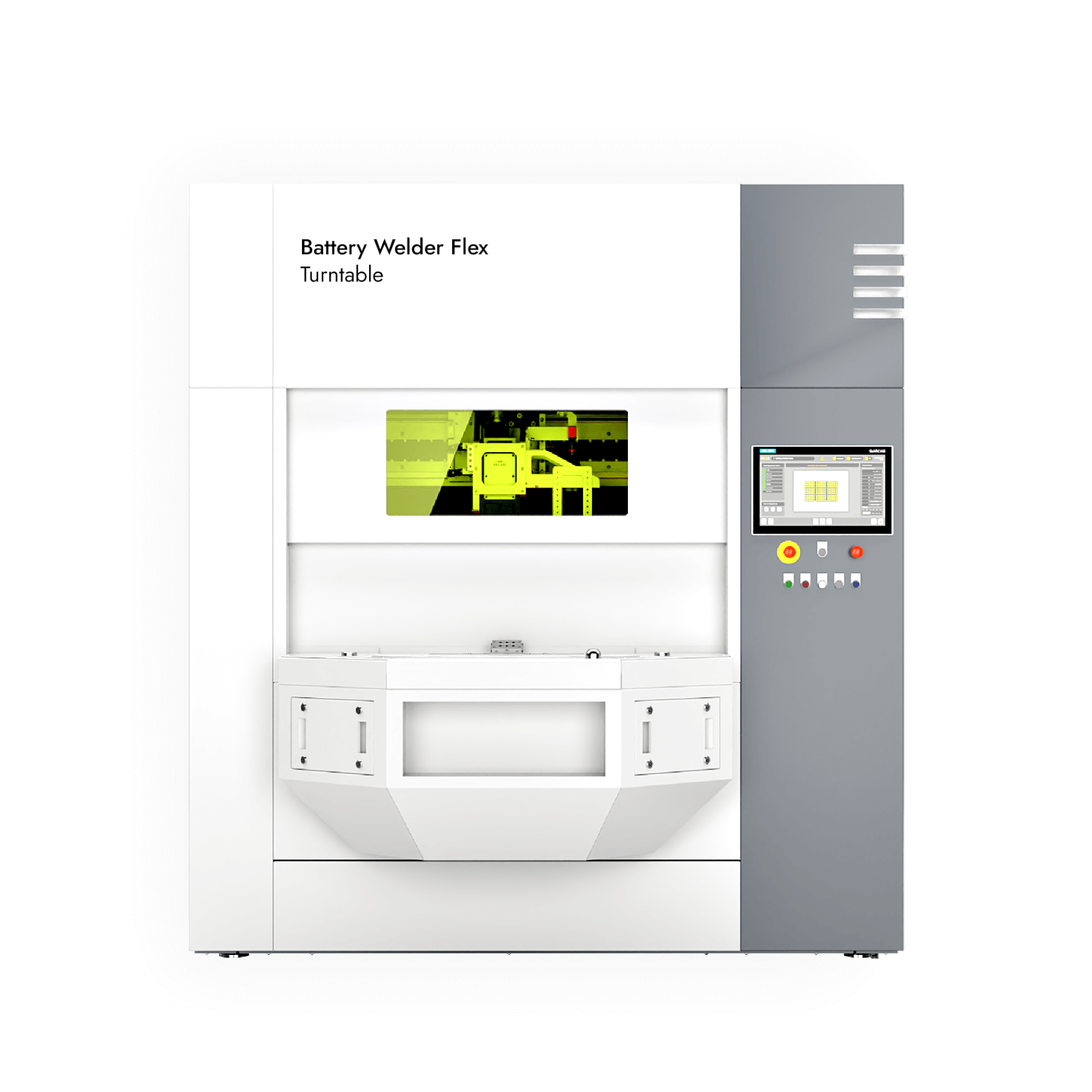

Battery Welder

Machines by RMA

Comprehensive solutions

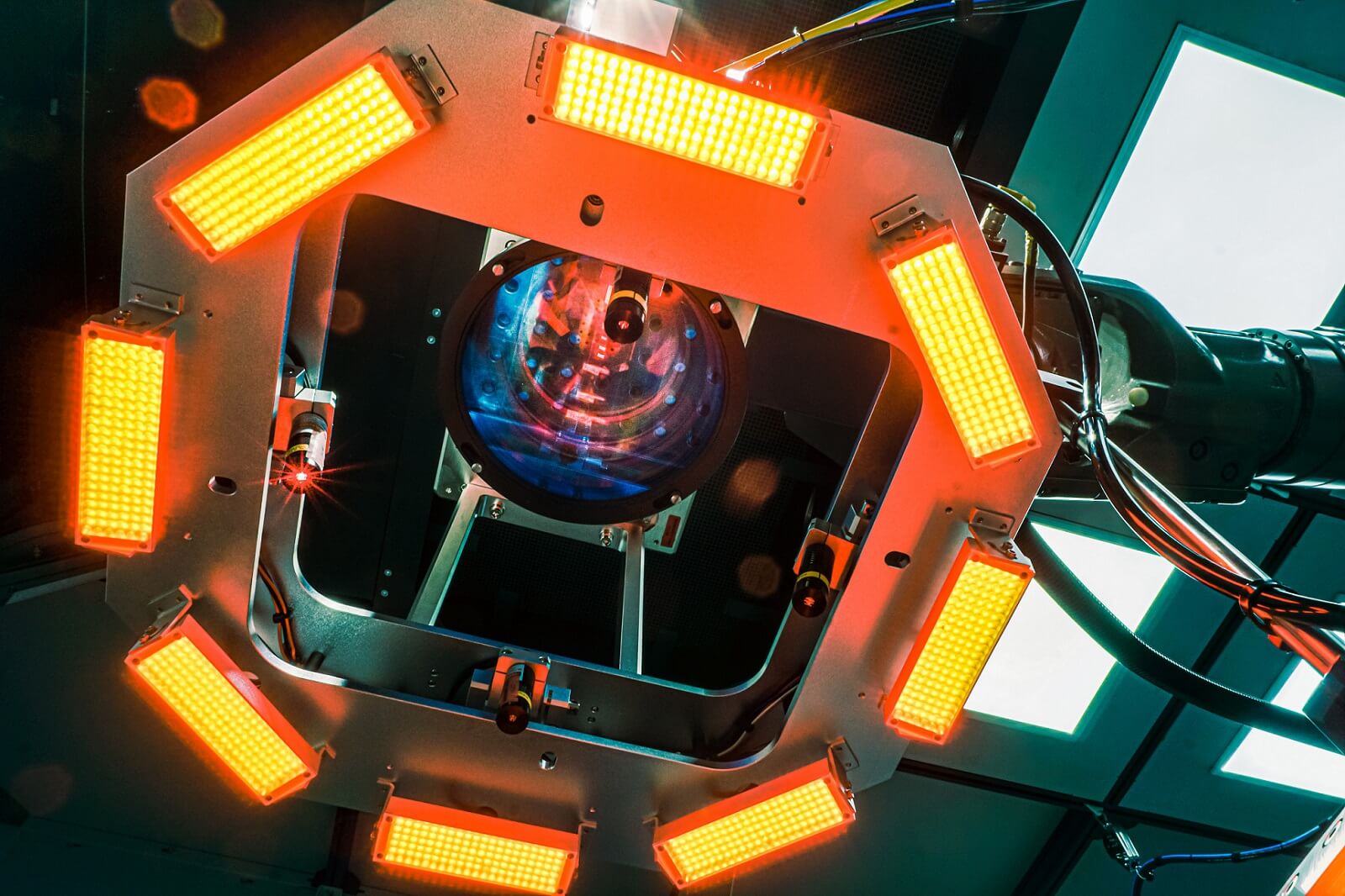

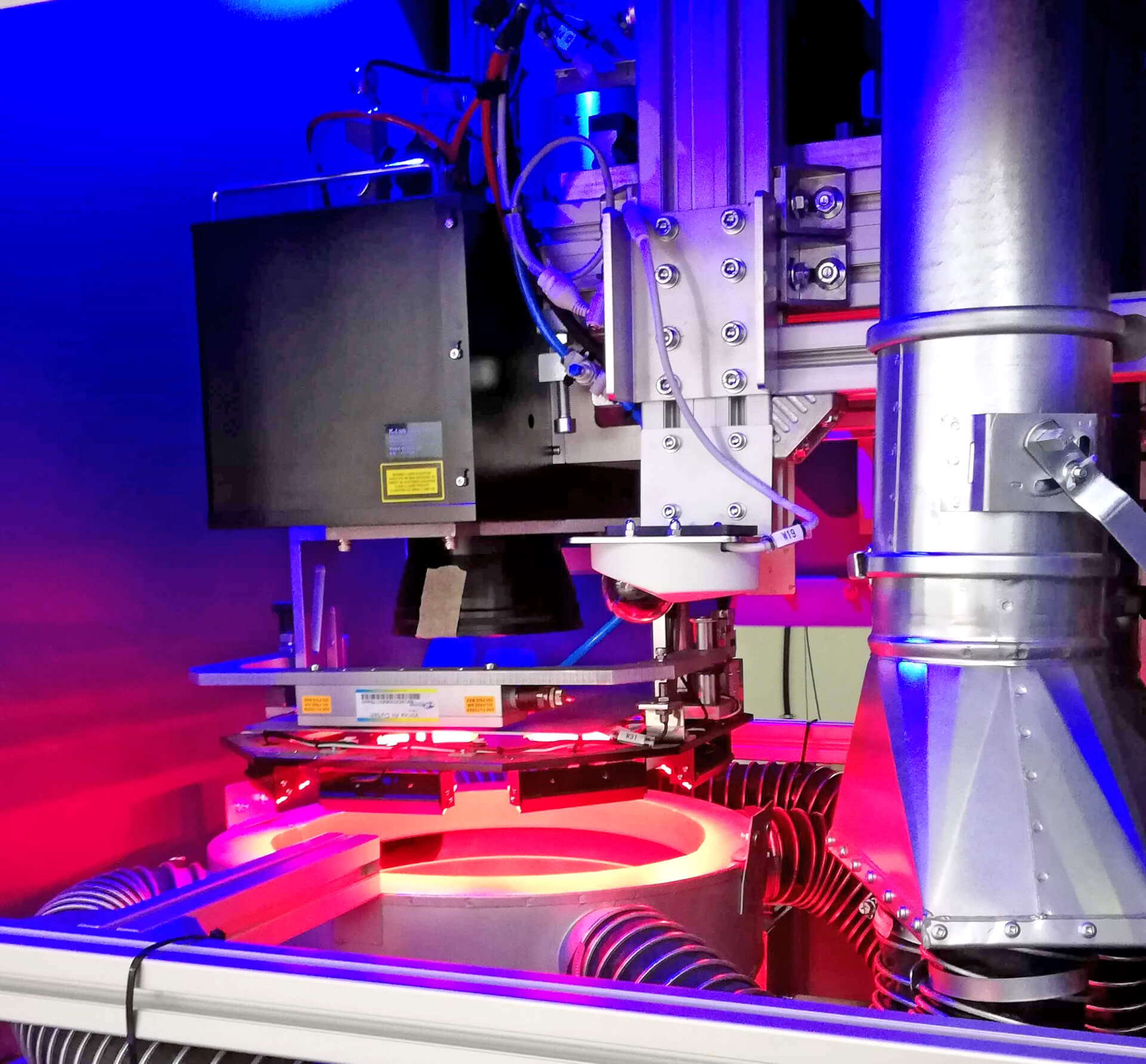

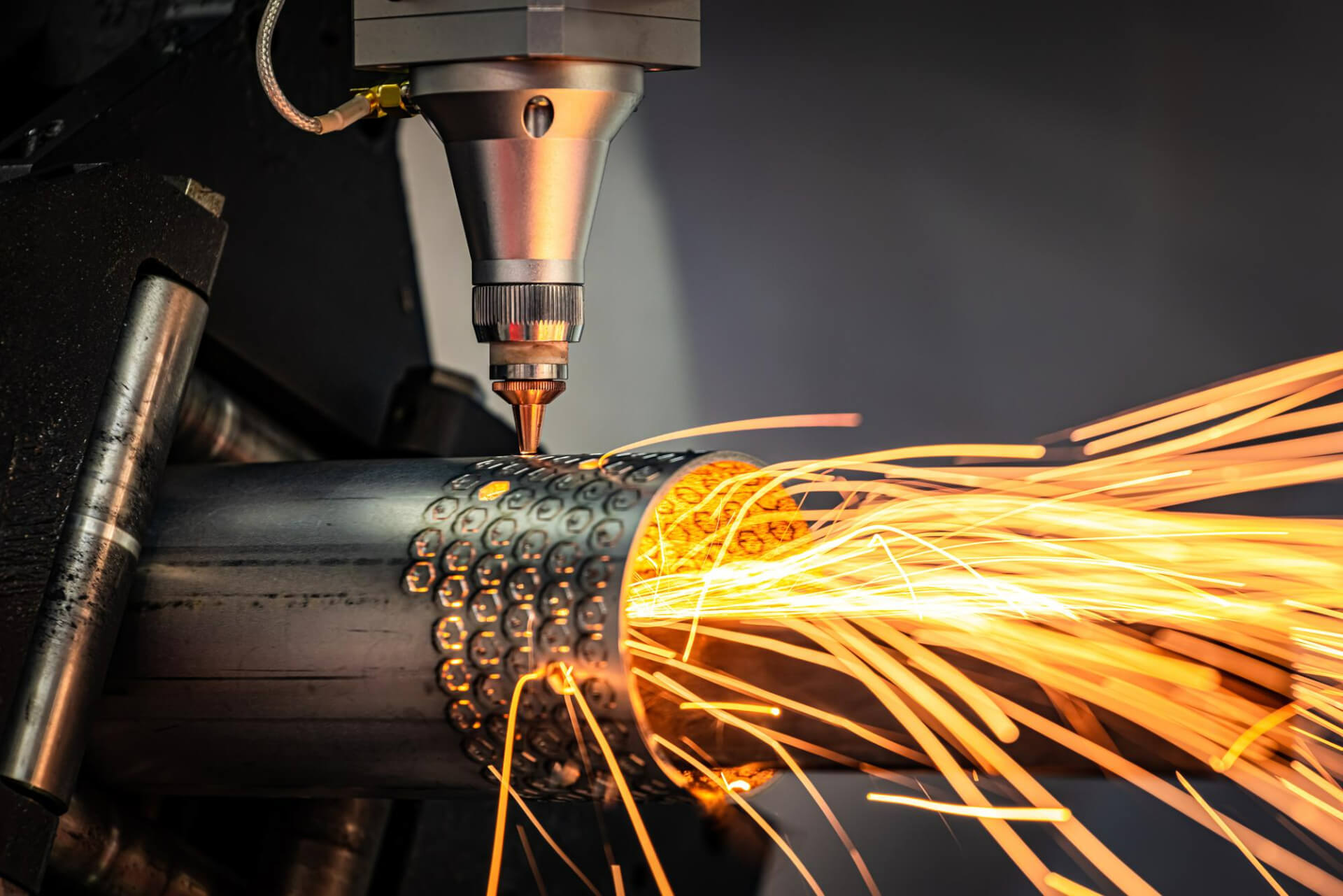

for laser welding of battery modules

Battery Pack

Laser Welding

Discover our innovative laser welding services and expert support to improve

Upcoming events The Battery Show 2026 Europe

June 9-11, 2026 / Stuttgart / Booth 1-I70